Your cart is currently empty!

The Production of St. John´s Wort Oil, Oleum Hyperici

Contents:

- Introduction

- Background Research

- Production Method

- Conclusion

- References

1. Introduction

The use of St. Johns Wort (SJW) (Hypericum perforatum) as a medical herb can be traced back to the ancient Greeks. Throughout ancient time and into the middle ages, its medicinal and (assumed) magical powers have been referenced. It appears in the writings of English herbalists of the 1600´s and its macerate, Oleum Hyperici, is listed in the first London Pharmacopeia [1]. It is this macerate that is the subject of interest and will be produced from the St. Johns Wort (SJW) plants growing in the permaculture experimental area.

Hypericum perforatum is a very well studied medicinal herb. Of interest are its ability to relieve the symptoms caused by disorders such as dermatitis, psoriasis and any other conditions that lead to dry, irritated skin. The anti-inflammatory , antimicrobial, antiviral, and wound-healing properties of SJW have been investigated by many researchers and its ability to relieve irritations to the epidermis has been confirmed through many studies [2-9].

2. Background Research

The macerate Oleum Hyperici is prepared from the fresh or dried flowering parts of the SJW plant. The use of a lipophilic solvent in the extraction process will favor the extraction of the phloroglucinol hyperforin and the naphthodianthrone hypericin [5]. These compounds are shown in Fig 1 below.

Heinrich et al. investigated the effect of various lighting and temperature combinations on the concentration of bioactive components of SJW macerates that had an extraction time of 28 days [10]. Also, in a following study, the extraction properties of 12 different fatty oils on the phytochemicals present in SJW was examined [11]. The results of their investigation into these factors has yielded the following results which are shown in the following graphics from the journal articles:

Fig 2 Comparison of the hyperforin and adhyperforin concentration of SJW macerates that were produced under various temperature and lighting conditions. D- Dark, AL- Artificial Light, SL-Sunlight. It can be seen that the hyperforin and adhyperforin concentrations of the macerate are negatively affected by exposure to light and seem to be best extracted at room temperature [10].

Fig 3 Comparison of the hyperforin and adhyperforin concentration of SJW macerates that were produced under various temperature and lighting conditions. D- Dark, AL- Artificial Light, SL-Sunlight. It can be seen that the hyperforin and adhyperforin concentrations of the macerate are negatively affected by exposure to light and seem to be best extracted at room temperature [10].

In Fig 4 below the results of the experiment that Heinrich et al. carried out on the extraction characteristics of 12 different fatty oils are displayed. The extraction was carried out at 50°C for a period of 7 days. The lighting conditions during the extraction process were not indicated.

Fig 4 Graphic A is a Comparison of the hyperforin and adhyperforin concentration of SJW macerates using various fatty oils. Under the given conditions it can be seen that macadamia nut oil (I´) had the highest concentration of hyperforin (36.7 mg/100g) and adhyperforin (4.6 mg/100g), approximately 2.4 times the concentration of the traditionally used olive oil sample, J’, (15 and 2 mg/100g respectively).

Graphic B indicates the measured concentrations of flavonoids that were also detected in each macerating oil [11].

From these results it can be seen that a mixture of hyperforin, adhyperforin, hypericin, and flavonoids are present to varying degrees in all macerates. The implication of these findings for the production of SJW oil are expressed quite well by the authors of the journal article:

“As can be deduced from the aforementioned results, none of the tested fatty oils achieved maximum yields of all considered target compounds investigated. Rather, as evaluated in the present study, solvents used for SJW extraction must be thoroughly selected depending on the therapeutic requirements of the resulting extracts.” [11]

With consideration of the results of Heinrich et al. the following choice of solvent and parameters and were made for the initial extraction experiments for the production of Oleum Hyperici:

Almond oil will be the solvent and the extraction will be preformed under conditions excluding light and at a temperature of 40°C. This choice of parameters and solvent does produce conditions that are to both favorable to hypericin and hyperforin and also the flavonoids. As a comparison, Almond oil will be used as a solvent and the transparent glass jar containing the macerating mixture will be placed on the windowsill and kept at ambient temperature conditions.

3. The Production of Oleum Hyperici

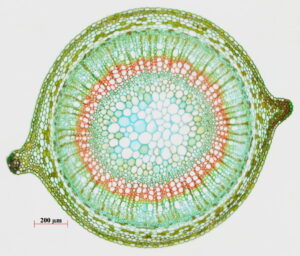

There are many species of Hypercum. To determine if the plant that is under consideration is the species preforatum, there are three distinguishing characteristics that will confirm its identity. These characteristics are described in Fig 6 below.

1) The stem is circular with two protrusions 180° from each other.

2) The flowers are bright yellow, have five petals and septals radiating from their center. If the flowers are rubbed between the fingers the skin will be turned to a dark reddish color by the secondary metabolites.

3) If the leaves are held up to the light, the pores will be visible and will appear as if the leaves are perforated.

Fig 6 Characteristics of Hypercum preforatum (Photos WIKI Commons)

Fig 7 SJW flowers were harvested at the permaculture project near Meißen, Germany.

Fig 8 The harvested SJW flowers are cleaned and inspected.

In order to isolate the macerating samples from light and maintain them at a temperature of 40°C as described by Heinrich et al. [10] , an isolation container was constructed from a Styrofoam insulation panel and a plant warming mat was placed inside as a heat source (Fig 9). The temperature inside the box was regulated by adjusting the width of the opening to a size that corresponded to the desired temperature. A datalogger was used to measure and record the temperature inside the box.

After the desired macerating time has been reached the oil is passed through a strainer to first separate the larger plant material and then through a 300 mesh (48 micron) filter. The final filtering is accomplished with a vacuum filtration system utilizing filter paper pictured below in Fig 10.

In Fig 11 below a sample of the filtered oil is shown. The filter paper in the vacuum filtering system removes material that had passed through the 300 mesh filter and produces a clear product.

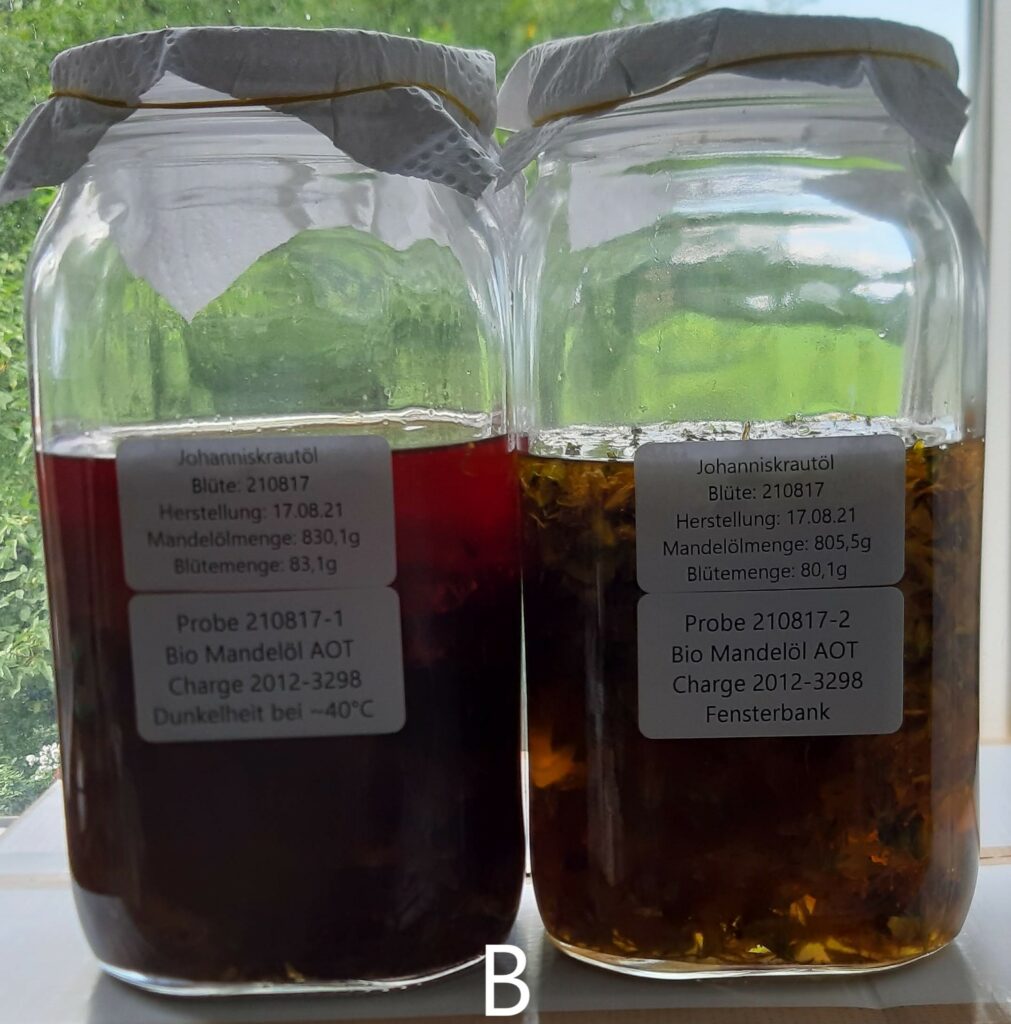

A comparison was made between the macerating conditions of darkness at 40°C and room temperature and the traditional method of placing the container in sunlight on a windowsill. The results of this comparison are shown in Fig 12 below.

As can be seen in the comparison of the filtered oils, the extraction that was carried out in the dark at 40°C is of a deeper red color and thus indicates a higher concentration of secondary metabolites than the sample extracted on the window sill in sunlight. This is consistent with the results of Heinrich et al. [10] and also the observed phenomena that the solubility of a solute is often directly proportional to temperature.

4. Conclusions:

The preparation of Johanniskraut oil carried out in the absence of light and at 40°C is visibility more efficient than the traditional method of preparation.

Vacuum filtering is necessary to remove the remaining plant material that had pass through a commonly available 300 mesh nylon filter.

5. References

1) Hobbs, C. “St. John’s wort–ancient herbal protector.” Pharmacy in history vol. 32,4 (1990): 166-9.

2) Prisăcaru, Anca Irina et al. “Evaluation of the wound-healing effect of a novel Hypericum perforatum ointment in skin injury.” Romanian journal of morphology and embryology vol. 54,4 (2013): 1053-9.

3) Birt, Diane F et al. “Hypericum in infection: Identification of anti-viral and anti-inflammatory constituents.” Pharmaceutical biology vol. 47,8 (2009): 774-782.

4) Okmen G, Balpınar N. THE BIOLOGICAL ACTIVITIES OF HYPERICUM PERFORATUM L. Afr J Tradit Complement Altern Med. 2016 Nov 23;14(1):213-218.

5) Wölfle, Ute et al. “Topical application of St. John’s wort (Hypericum perforatum).” Planta medica vol. 80,2-3 (2014): 109-20.

6) Mansouri, P et al. “The impact of topical Saint John’s Wort (Hypericum perforatum) treatment on tissue tumor necrosis factor-alpha levels in plaque-type psoriasis: A pilot study.” Journal of postgraduate medicine vol. 63,4 (2017): 215-220.

7) Barnes, J et al. “St John’s wort (Hypericum perforatum L.): a review of its chemistry, pharmacology and clinical properties.” The Journal of pharmacy and pharmacology vol. 53,5 (2001): 583-600.

8) Lyles, James T et al.“The Chemical and Antibacterial Evaluation of St. John’s Wort Oil Macerates Used in Kosovar Traditional Medicine” Frontiers in microbiology vol. 8 1639. 8 Sep. 2017

9) Silva, Ana R et al. “Hypericum genus cosmeceutical application – A decade comprehensive review on its multifunctional biological properties” Industrial Crops and Products vol. 159 Jan. 2021, 113053

10) Heinrich, M et al. “Comprehensive phytochemical characterization of St. John’s wort (Hypericum perforatum L.) oil macerates obtained by different extraction protocols via analytical tools applicable in routine control” Die Pharmazie vol. 72,3 (2017): 131-138.

11) Heinrich, M. et al. “Characterization of Hypericum perforatum L. (St. John’s wort) macerates prepared with different fatty oils upon processing and storage” Phytochemistry Letters Vol. 20, June 2017, Pages 470-480